Nord-Lock created the original wedge-locking technology that secures bolted joints, even when exposed to severe vibration and dynamic loads. It is impossible for our products to loosen unintentionally due to the wedge created underneath the bolt head and nut.

WEDGE-LOCK WASHERS

Nord-Lock wedge-locking washers utilise tension instead of friction in order to secure bolted joints exposed to severe vibration and dynamic loads.

Over the operational life cycle, Nord-Lock washers offer increased operational reliability and lower maintenance costs, while significantly reducing the risks of production stops, accidents and warranty claims.

| How it works? | Download Catalog |

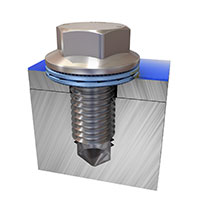

X-SERIES WASHERS

The Nord-Lock X-series washers combine Nord-Lock wedge-locking with an innovative spring effect, offering the highest security against spontaneous bolt loosening and slackening.

This product is the optimum choice when you have both vibrations and applications with risk of slackening such as short clamp length, multiple clamped parts, gaskets, soft metals, plastic composites, coatings and thermal cycling.

Nord-Lock X-series steel washer promises the highest corrosion resistance in the market, it is tested at least 1,000 hours in the Neutral Salt Spray Test.

How it works?

Technology

Nord-Lock created the original wedge-locking technology that secures bolted joints, even when exposed to severe vibration and dynamic loads. It is impossible for our products to loosen unintentionally due to the wedge created underneath the bolt head and nut.

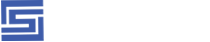

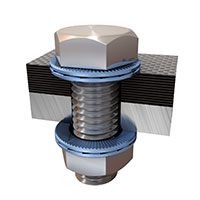

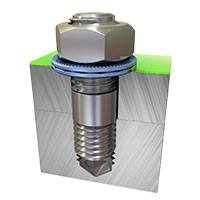

WEDGE-LOCKING TECHNOLOGY

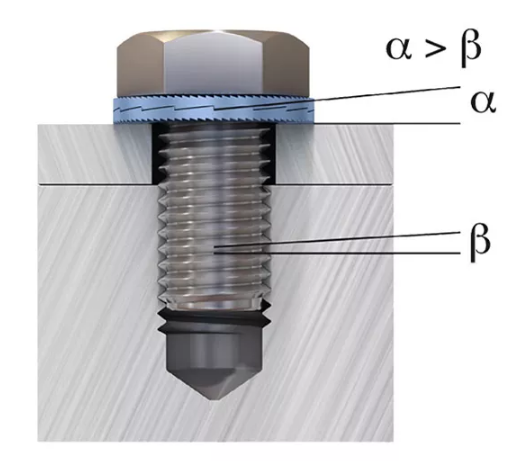

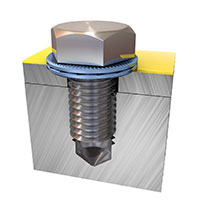

Nord-Lock wedge-locking technology secures bolted joints with tension instead of friction. The system is composed of a pair of lock washers with cams on one side and radial teeth on the other.

Nord-Lock wedge-locking products secure the fastener in a joint which cannot be loosened even when subjected to extreme vibration or dynamic loads. The Nord-Lock range includes steel construction washers, wheel nuts, combi bolt washers and custom solutions.

Installation guide

Tapped Holes

Counterbores

Through holes

Stud bolts

Application